The Precision Forming Technology Center is engaged in the research of near-net forming processes and intelligent forming equipment such as precision casting, precision forging, and precision stamping. In recent years, the center has undertaken a number of major projects such as the National Key R&D Program, major projects of National Natural Science Foundation of China, and the ITER program. Its research results have won 1 second prize for national technological invention, 7 first prizes for provincial and ministerial scientific and technological progress and authorized more than 100 national invention patents. The center has published more than 500 papers in important journals and academic conferences at home and abroad.

The center has strong teaching and scientific research capabilities, with 22 full-time teachers, including 8 professors, 11 associate professors/associate researchers, and 3 lecturers.

Main research directions:

1) Precision casting forming technology for high-performance aluminum (magnesium) alloys, Ti alloys, TiAl intermetallic compounds, amorphous alloys and high-entropy alloys complex components

2) Precision plastic forming process, multi-scale simulation calculation, new die & mould structure design, and intelligent plastic forming equipment and process of High-Performance Lightweight parts in automobile, aerospace, weapons and other fields

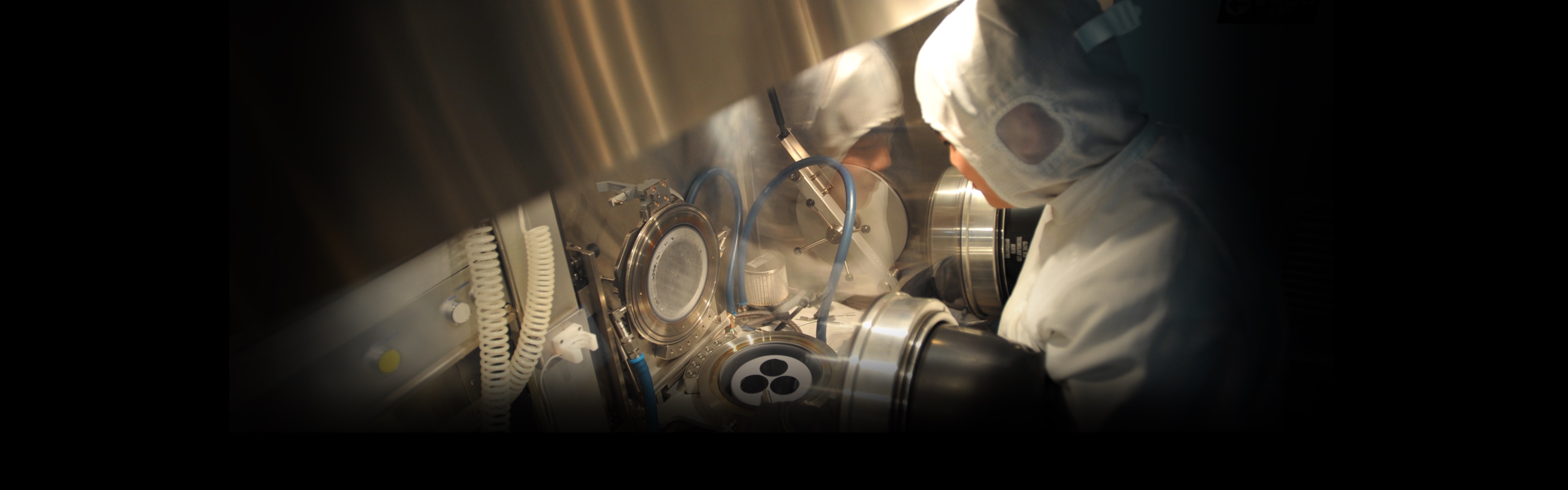

3) Forming technology of ODS low activation steel and heat sink copper alloy, high-performance tritium-resistant coating, structure-function integrated self-passivation W alloy; nano/micro ceramic particle reinforced metal matrix composites forming technology; forming technology of high-performance complex aluminum/magnesium, aluminum/iron, aluminum/copper and other bimetal composite components.

4) High-performance, low (no) pollution green sand-casting method and process; a variety of casting solid waste recycling technologies.

5) Deposition molding, electrospinning, electrostatic direct writing, frozen printing of biological materials such as bioceramics and natural polymers; materials, processes and equipment for multi-head micro-extrusion 3D printing ceramic casting cores; integrated casting of metal/ceramic components based on 3D printing technology.

Members:

Professor: WU Shusen, ZHANG Xianglin, CAI Qizhou, WANG Guilan, FAN Zitian, WANG Xinyun, DONG Xuanpu, LIU Xinwang

Associate Professor: LUO Yunhua, XUE Lihong, JIN Junsong, LI Heping, LV Shulin, DENG Lei, JIANG Wenming, GONG Pan, GUO Wei, ZHANG Mao

Lecture: WU Bin, TANG Xuefeng, YIN Shengming